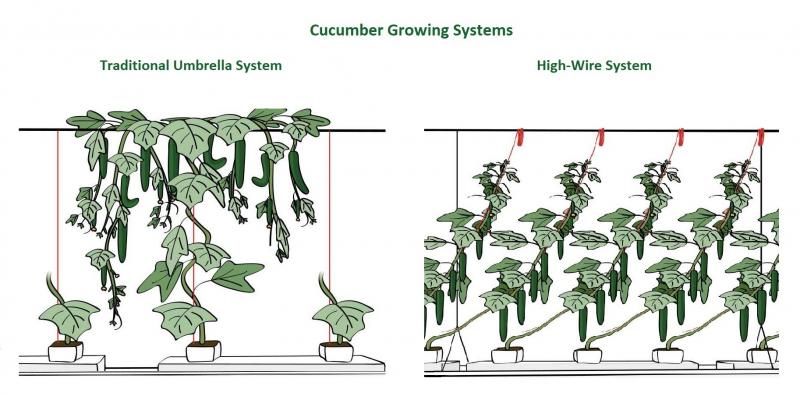

Cucumber is one of the most important greenhouse crops in Saudi Ariba. a very fast-growing plant. It takes only 2 to 3 weeks after the transplant of young cucumber plants for harvest to start. The downside of this fast-growing is that if the plant is trained to grow along a vertical wire (the training-wire), it quickly reaches the fixing point of the wire. This fixing point of the training-wire is called the crop-wire. Traditionally, when this point is reached, growers simply bend the top of the crop over the crop-wire. Due to gravity, the top of the crop is then growing downward. When this downward growing top of the crop gets some length (say 1,5 meters), the top is picked up and bent over the crop-wire again. This can be repeated a third time, but after that, the bunch of leaves and stems becomes that messy that the crop has to be removed. After the removal of the old crop, a new crop has to be planted. Due to this practice, cucumber cultivation has traditionally three cycles a year and therefore also three times some weeks without production (ESTIDAMAH cucumber report, 2018).

ESTIDAMAH has tested a new cropping system called high wire system, in this case, the training-wire can be elongated and shifted aside to cope with the continuously growing stem (up to 60 cm a week). Of course, the continuously growing stems will just as well create a large bunch of stems, but in the high wire system, the bunches are from de-leaved stems and are at the bottom side of the crop. Therefore, the bunch of stems will be much less messy. This makes that one crop cycle can stay productive for a longer period. Per kg of product, this reduces the initial costs for seeds, propagation and planting and it reduces the number of weeks without production (ESTIDAMAH cucumber report, 2018).

Estidamah's experimental results on high wire cucumber in a Low-tech compartment showed that by adopting the carousel system in a high wire cultivation system, the cucumber crop stays productive for a longer period. The High Wire crop had a harvest period of 146 days, whereas in the reference (umbrella system) the crop was worn out after a harvest period of 110 days. Besides, in the High wire system, the fruit quality and productivity remained equal for the whole period where the reference greenhouse showed 10 to 20% malformed fruits and a serious drop in productivity by the end of the harvest period (ESTIDAMAH cucumber report,2018).

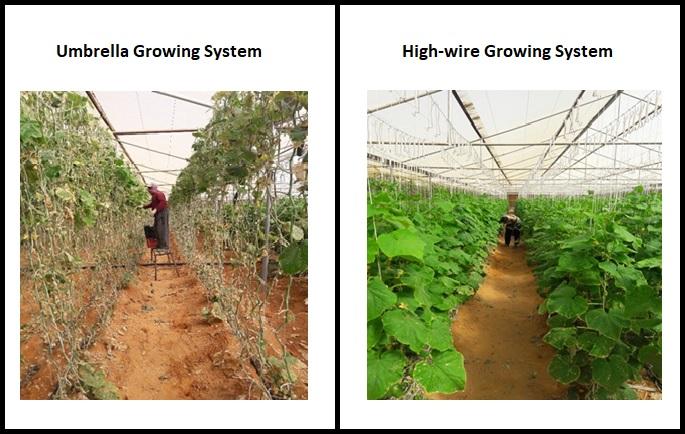

In order to improve farmers' income via increasing cucumber productivity, a second field trial was conducted to evaluate cucumber productivity by using three cropping systems in one med-tech fiberglass greenhouse (5000 m2 each) in a commercial farm. The greenhouse consists of 10 units; the cultivated area of each unit is 468 m2. The experimental trial was carried out in five units (Two units for umbrella systems with one stem (Traditional cropping system), two units for the high-wire system with two stems (Fig.1) and one unit for umbrella system with two stems).

Fig. 1: Cucumber growing systems used in Med-Tech greenhouse at the commercial Farm.2020.

Experiment setup:

The experiment was carried out in a commercial farm in the Thadiq near RIYADH using a med-tech fiberglass greenhouse (Picture 1). The area of the greenhouse is 5000 m2, with 130 m length and 38 m width. Greenhouse height from the middle 5.30 m and from the side 2.70 m. The greenhouse consists of 10 units, the cultivated area of each unit is 468 m2 (Table 1). In this greenhouse, a pad and fan automated cooling system was used. Two thermometers were installed. Half of the fans start automatically running when the inside air temperature is above 24oC and the other half of the fans start when the inside air temperature is above 28oC.

Picture1. Med-Tech Fiberglass Greenhouse Commercial Farm, Thadiq, Riyadh

Table 1: Greenhouse description and planting density

| GH Length | 130m | No. of rows per unit | 13 |

| GH width | 38m | No. of plants per row | 108 |

| GH area | 5000 m2 | No. of plants per unit | 1404 |

| GH side height | 270 cm | Plant density | 3 Plants/m2 |

| GH mid-height | 530cm | Plant spacing within rows | 35 cm |

| Plant wire height | 250 cm | Spacing between rows | 100cm |

| No. of units per GH | 10 | Temp. A set point 50% fans running | 24 |

| Planting unit size | 13*36 m | Temp. B set point for the rest 50% fans | 28 c |

| Planting unit area | 468 m2 | No. of workers per greenhouse | 2.5 |

Cucumber seed (Al-Farid) from Rijk Zwaan was sown directly inside the greenhouse on the 1st of June 2020. The experiment was done using 5 units out of 10. Table (2) present the layout of the experiment. For high-wire and umbrella system using two stems, seedlings top cut was done after the appearance of the fourth true leaves on 16th June 2020 to allow two new axillary buds to grow from the second and the third leaf base (Picture 2). Table 3 showed the important dates of this trial.

Table 2: Experiment Layout inside the Greenhouse

| Unit No. | Crop | Variety | Treatments | Remarks |

| 1 | Cucumber | |||

| 2 | Cucumber | |||

| 3 | Cucumber | |||

| 4 | Cucumber | |||

| 5 | Cucumber | Al-Farid | Umbrella system | One stem |

| 6 | Cucumber | Al-Farid | High-wire | Two stems |

| 7 | Cucumber | Al-Farid | Umbrella system | Two stems |

| 8 | Cucumber | Al-Farid | Umbrella system | One stem |

| 9 | Cucumber | Al-Farid | High-wire | Two stems |

| 10 | Cucumber |

Table 3. Field Trial Important Dates

| Activity | Umbrella System One stem |

Umbrella System Two stems |

High-wire System Two stems |

| Direct seed sowing | 01-June-2020 | 01-June-2020 | 01-June-2020 |

| Top cut to have two stems | - | 16-June-2020 | 16-June-2020 |

| First harvest | 06-July-2020 | 06-July-2020 | 06-July-2020 |

| Last Harvest | 15-August-2020 | 15-August-2020 | 28-September-2020 |

| Crop cycle from seed sowing (Days) | 76 | 76 | 120 |

Picture 2: Cucumber plants inside the Greenhouse, Left - Direct Seeding and Right - Seedlings top cutting on June 16 to initiate two lateral stems.

Water Analysis and Fertilizer Recommendation

| pH | 6.06 |

|---|---|

| EC (ds.m-1) | 0.057 |

| TDS (mg/L) | 36.5 |

| Ca (mg/L) | 1.5 |

| Mg (mg/L) | 0 |

| Na (mg/L) | 10.9 |

| K (mg/L) | 0.3 |

| HCO3−1 (mg/L) | 2.6 |

| Cl (mg/L) | 13.8 |

| S (mg/L) | 5.1 |

| NO3 (mg/L) | Less than 0.5 |

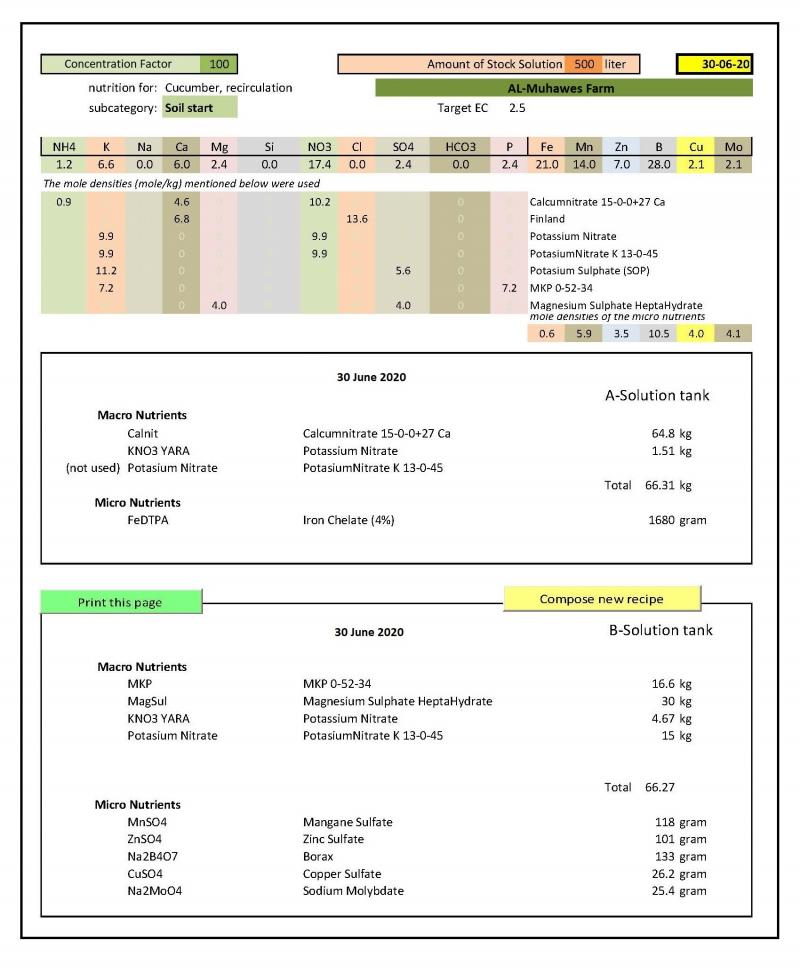

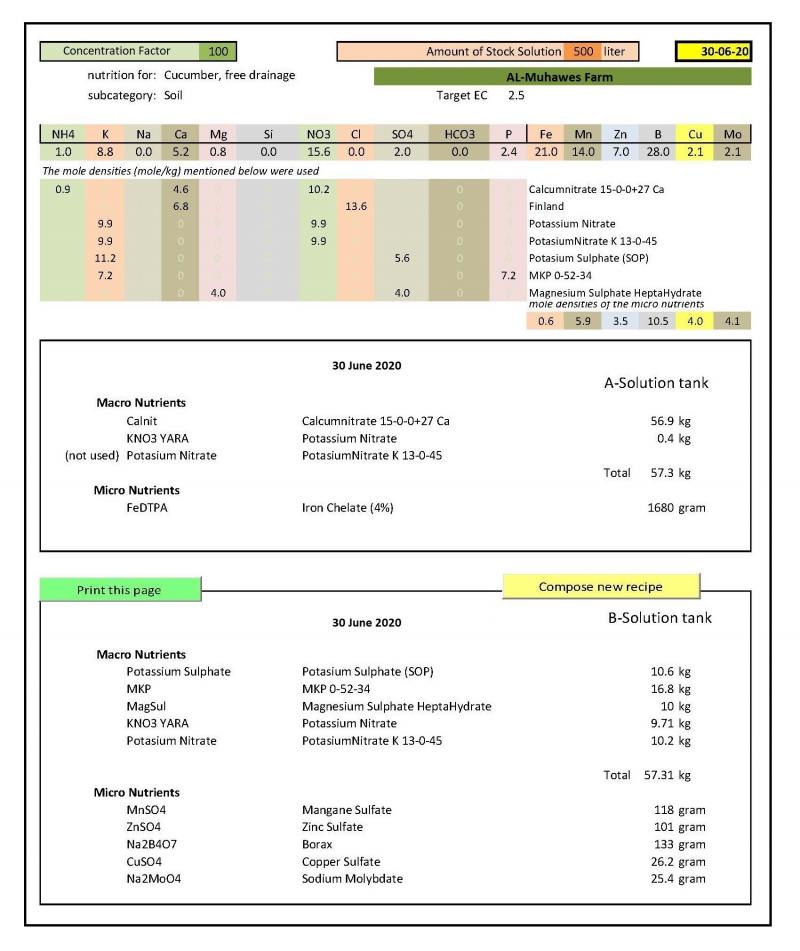

According to water analysis, the following startup and production stage fertilizer recommendation was prepared by Estidamah fertigation expert.

Fertilizer Recommendation for Startup Stage as prepared by Estidamah Fertigation Expert.

Fertilizer Recommendation for Production Stage of Cucumber Growth as prepared by Estidamah Fertigation Expert.

Testing a new cropping system called high-wire system in comparison to the traditional Umbrella system

- High-Wire Cucumber Growing System in Med-Tech Glasshouse at the commercial farm in comparison to Umbrella system

Total cucumber yield of the high-wire growing system was greater by 20% than that of the umbrella system.

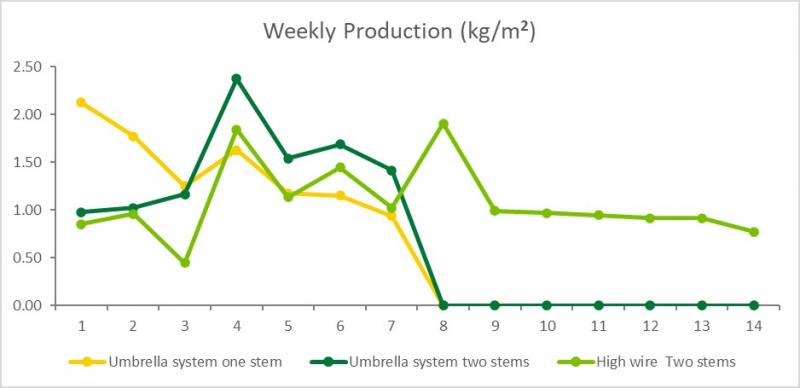

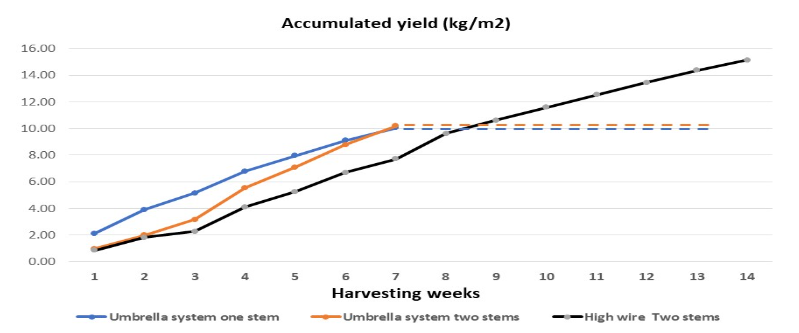

The cucumber fruit harvest was started on the 6th of July 2020. Results showed that, within the first 3 weeks of harvest, the yield of the Umbrella growing system using one stem without top cutting (5.15 kg/m2) was higher than the umbrella system using two stems and top cutting (3.17 kg/m2) and the high-wire system using two stems and top cutting (2.26 kg/m2) (Table 7). These results indicated that top cutting caused the delay in cucumber harvesting for about 3 weeks when using direct field seeding. Furthermore, these results showed that about 51% of the total yield in umbrella system without top cutting was harvested in the first three weeks, while with top cutting, 31% of the total yield was harvested when using umbrella system and only 15% of the total yield was harvested when using high wire system (Table 7).

During the summer growing season, the harvesting period for the traditional umbrella system using one or two stems did not exceed seven weeks (50 days), and the plants had almost dried (Picture 3 A), while when using the high-wire system, the harvesting period can last for 14 weeks (100 days) under such growing conditions without any symptoms of plant drying (Picture 3 B).

Our results showed that the harvesting yield from week 4 to 7 was about 49% of the total yield in umbrella system using one stem and 69% when using umbrella system and two stems, while it formed only 36% of the total yield when using high-wire and two stems (Table 7). This indicates that using a high-wire system provides constant yield production all over the harvesting period compared to an umbrella system.

Figure 2. Weekly production (kg/m2) of cucumber plants grown by three growing systems at the commercial farm, 2020.

Table 7: Weekly and Total cucumber yield using three growing systems at the Commercial Farm 2020.

| Weeks of Harvest | Umbrella System 1 stem | Umbrella System 2 stems | High-wire 2 stems |

| 1 | 2.13 | 0.98 | 0.85 |

| 2 | 1.77 | 1.02 | 0.96 |

| 3 | 1.25 | 1.17 | 0.45 |

| 4 | 1.63 | 2.38 | 1.84 |

| 5 | 1.17 | 1.54 | 1.14 |

| 6 | 1.15 | 1.69 | 1.45 |

| 7 | 0.94 | 1.42 | 1.02 |

| 8 | 0 | 0 | 1.91 |

| 9 | 0 | 0 | 0.99 |

| 10 | 0 | 0 | 0.97 |

| 11 | 0 | 0 | 0.95 |

| 12 | 0 | 0 | 0.92 |

| 13 | 0 | 0 | 0.92 |

| 14 | 0 | 0 | 0.77 |

| Total Yield (kg/m2) | 10.04 | 10.19 | 15.13 |

| Weeks (1-3)% of total yield | 51 | 31 | 15 |

| Weeks (4-7)% of total yield | 49 | 69 | 36 |

High-wire increased harvesting period (85 days) as compared to Umbrella (41 days), and also improved class A fruits up to 89%

The results of the accumulated yield for the three growing systems showed that the yield of the umbrella system (one or two stems) was greater than that of the high-wire system in the first 8 weeks of harvest (Fig.3), while starting from week 9, the accumulated yield of the high-wire system was greater than that of umbrella system because the plants of umbrella system had dried and no further production from these two treatments was obtained.

Figure 3. Accumulated Yield of three growing systems at the commercial farm. 2020.

Total Cucumber Yield

The total cucumber yield of the high-wire growing system was greater than that of the umbrella system. The average total yield of the high-wire system was 15.13 kg/m2, while for umbrella system using one stem was 10.04 kg/m2 and for umbrella system using two stems was 10.19 kg/m2. Results showed that the high-wire system increased yield by 49 to 51-% as compared to the umbrella system using two stems or one stem, respectively (Table 8).

Results also showed that water-use efficiency ranged from 92.0 l/kg for the umbrella system to 97.8 l/kg for the high-wire system (Table 8). Energy and labor costs (SAR/m2/crop cycle) were also higher when using the high-wire system compared to the umbrella system because of the long crop cycle (Table 8).

Table 8: Total Yield, Water Use Efficiency, Energy and Worker costs of cucumber plants when grown in three growing systems.

| Item | Umbrella 1 stem | Umbrella 2 stems | High-wire 2 stems |

| Growing cycle (Days) | 76 | 76 | 120 |

| Harvesting period (Days) | 41 | 41 | 85 |

| No. of harvest | 21 | 21 | 43 |

| Average yield (kg/m2) | 10.04 | 10.19 | 15.13 |

| Average plant yield (kg/plant) (3 plants/m2) | 3.35 | 4 | 5.04 |

| Total irrigation water (l per m2) | 312.3 | 312.3 | 493.1 |

| Total cooling water (l per m2) | 624.7 | 624.7 | 986.3 |

| Total water consumption (l/m2) | 937 | 937 | 1479.4 |

| Water-Use Efficiency (l/kg) | 93.3 | 92 | 97.8 |

| Energy cost (SAR/m2/ crop cycle) | 0.92 | 0.92 | 1.41 |

| Labor cost (SAR/m2/crop cycle | 2.69 | 2.69 | 4.14 |

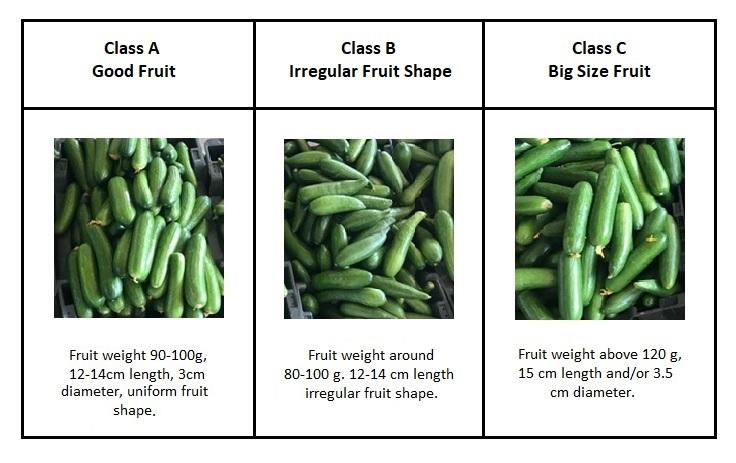

Fruit Yield Classification

Harvested fruits in nine harvesting dates from the three growing systems were used to classify fruit yield quality. For each growing system, the fruit was separated by the grower into three classes:

- Class A: Fruit weight 90-100 g, 12-14 cm length, 3 cm diameter, uniform fruit shape.

- Class B: Fruit weight around 80-100 g. 12-14 cm length irregular fruit shape.

- Class C: Fruit weight Above 120 g, 15 cm length, and/or 3.5 cm diameter.

The description and photo for each class are presented in table (9)

Table 9: Harvested fruit classification from High-wire and Umbrella systems (Data average of 9 harvest dates)

The results showed that using a high-wire system improve class A yield (56.6% of the total yield) as compared with an umbrella system (45.2%) (There were no differences between umbrella systems using one or two stems regarding fruit quality), while class B yield was not strongly affected by the growing system (Table 10). On the other hand, Class C yield was reduced by a high-wire system (12.5% from total yield) as compared with an umbrella system (23.1%).

Table 10: Fruit yield classification according to farmer practices (data average of nine harvesting dates).

| Class A | Class B | Class C | Total | |

| Good Fruit | Irregular Fruit Shape | Big Size Fruit | ||

| Umbrella system | 4.54 | 3.18 | 2.32 | 10.04 |

| 45.20% | 31.80% | 23.10% | 100% | |

| High-wire system | 8.56 | 4.68 | 1.89 | 15.13 |

| 56.60% | 30.90% | 12.50% | 100% | |

| Avg. price per Box (10 kg) in SAR | 32 | 14 | 12 | |

| Avg. price per Kg (SAR) | 3.2 | 1.4 | 1.2 | |

| Total Selling Price (SAR/m2) | ||||

| Umbrella system | 14.5 | 4.45 | 2.78 | 21.77 |

| High-wire system | 27.4 | 6.55 | 2.27 | 36.21 |

Conclusions

- According to the results of this trial, cucumber yield (kg/m2) was improved by 49 to 51-% when using a high-wire system as compared with an umbrella system using two stems or one stem, respectively (Table 8).

- The harvesting period was doubled by a high-wire system as compared with an umbrella system (from 41 to 85 days) (Table 8).

- Fruit quality was also improved by increasing the percent of class A yield up to 89%, and class C yield was decreased by 19% when using high wire as compared with the umbrella system (Table 10).

- Total cucumber fruit selling price per m2 was improved by 66% when using a high-wire system as compared with an umbrella system.

- Using a high-wire system and two stems per plant (Top cut) in direct seeding practices delay fruit harvest by 3 weeks as compared with a single stem (no top cut).

- In summer (June) cucumber greenhouse cultivation, 50% of total fruit yield produced in the first 3 weeks when using umbrella system, while when using high wire system 15% of total yield was produced in the first 3 weeks. These results indicate that using a high-wire system fruit harvesting was more stable with time than an umbrella system.

Recommendations

In order to have a better result, we recommend the following:

- Doing the same experiment on another planting date (less temperature).

- Practice a high-wire training system in a complete greenhouse (all greenhouse areas).

- Allocate small size greenhouse for seedling production to avoid extra operation cost 5000m2 greenhouses.

- Growers should practice good hygiene protocol to avoid insect infection including crop rotation in each greenhouse compartment.